An Introduction to Sugar and Sugar Substitutes (Natural)

This post may contain affiliate links. Please read our disclosure policy.

An introduction to sugar and sugar substitutes – including the process of making sugar – from field to table, different types of sugar, and more FAQs!

Having recently shared a post on baking powder vs. baking soda (after sharing the information on my Instagram stories), everyone seemed to enjoy this type of content – exploring more about the ingredients we use (myself included). So I’m back again, this time with an introduction to sugar and natural sugar substitutes.

Within this post, I’ll take you through where sugar comes from, how it is made, a brief introduction to several other sugar substitutes, and several FAQs too.

Want to save this recipe?

Sugars vs. Sugar

I thought it was important to start this blog post with an important distinction. When discussing “sugars,” we’re referring to the broad category of sugars (carbohydrates), including:

- Monosaccharides (including glucose, galactose, and fructose) AND

- Disaccharides which are a type of compound sugar comprising of two monosaccharides (including sucrose, maltose, lactose, etc.).

These can be naturally occurring in all kinds of foods, such as fruit, vegetables, nuts, dairy, etc. They can also be extracted or be human-made.

This blog post is specifically discussing “sugar” as an ingredient (granulated, white, table). This refers to sucrose – a disaccharide comprising glucose and fructose found in many green plants. Most “sugar” we consume, however, is from sugar cane or sugar beets.

The Different Types Of Sugar

The amount of molasses left on the sugar crystals (or added back to the crystals) determines what type of sugar it is. Alongside white, light brown, and dark brown sugar are several types in-between.

Granulated Sugars

- Raw cane sugar: is a partially processed sugar also called “turbinado” or “demerara” sugar. It is almost “blonde”/mild brown color – with larger crystals than regular brown sugar.

- Muscovado: also called “Barbados”, is another type of unrefined cane sugar before any molasses have been removed. It is coarse, sticky, and very dark brown with a strong molasses flavor.

- Brown sugar: light and dark brown sugars are a combination of white sugar with various amounts of molasses – which means they are “wetter” and clump more. It also allows for baked goods that are chewier and retain more moisture. Check here how to make it at home.

- White sugar: comes in coarse, “regular” granulated, and super-fine crystal sizes – which are naturally present due to the crystallization process following the above processing.

- Powdered sugar: is simply granulated sugar that has been ground and sieved into a smooth powder. Most commercially sold versions will also contain an “anti-caking” agent such as cornstarch too.

- Coconut sugar: is from the sap in the flower buds of the coconut palm tree (not the coconut fruit!). The sap is boiled into a syrup that crystallizes and is dried and ground into coconut sugar. It tastes similar to brown sugar (with a twist) and is caramel/blonde colored.

- Fruit Sugar: can come from several sources and is generally from drying and grinding the fruit – such as dates.

Liquid Sugars

- Honey: is the sugar-rich nectar collected by bees from flowers and deposited (regurgitated from the bees – sorry, but it’s true!) into the honeycomb – which breaks down the sugars and becomes liquid honey. Though raw honey is edible, most commercial honey will filtrate the honey first to remove the impurities (bee pollen, beeswax, insect parts, etc.).

- Sap syrups: such as maple syrup which is extracted as sap and boiled into a thick syrup, then filtered and sold. Agave syrup takes a little more processing as it needs to be broken down into sugar first before concentrating into syrup.

- Corn syrup: corn syrup is made from the corn’s starch, which is combined with hydrochloric acid and heated to be broken down into glucose and processed to become corn syrup. This can then be further processed into an even sweeter version ‘high fructose corn syrup.

- Fruit syrups: such as date, grape, pomegranate, etc., and is made by combining the fruit with water, blending, filtering, and heating it into a nectar/syrup – sometimes with extra sugars added (not usually in the case of date syrup). It often contains a lot of the vitamins and minerals from the fruit too.

Side note: There are, of course, artificial sugar-free sweeteners too – like stevia and erythritol – but if I get into them, this post will become a whole book! Maybe I’ll save that for another day. Let me know in the comments if you’d like me to do another post on artificial sweeteners.

Where Does Sugar Come From?

Quick answer – mostly from sugar cane (which look similar to bamboo and are grown in tropical climates including Hawaii, South Africa, Brazil, etc.) or sugar beets (a type of root crop where the sugar is stored in the root, not stalk/leaves; it can be grown in more temperate areas like throughout Europe, the United States, Canada, etc.)

The sugar is made within the plant’s leaves and stored as a juice in the stalks of the sugar cane (or within the root of the sugar beet). Once harvested, the cane juice is extracted and goes through several processes, including purification, filtration, and crystallization into raw sugar. This can then be further refined.

Fun fact: Apparently, 55-60% of sugar produced in the US is made from sugar beets.

Sugar Cane

Please note that this is the information I know to be correct from all the research I’ve done on the matter. This may not be the case 100% of the time – in all processing plants.

Harvest & Extract The Juice

First, the cane is harvested from sugarcane fields and gets washed. This sugar cane then passes through a milling machine, which breaks the branches/structure into smaller pieces that are easier to process.

The sweet juice is then extracted from the fiber using a milling process that is repeated consecutively several times (around 5-6) to get as much of the juice as possible. This juice is what will become our sugar and will be clarified, concentrated, and crystallized.

Process The Cane Juice

First, it’s put through a process called sulphitation. Sulphitation is a purification process that uses a mixture of lime and sulfur dioxide (SO2) gas, which helps to control the pH level of the juice, and also works as a color blocker – so the juice doesn’t darken as much in later processing (during the evaporation stage) and turning the juice from a brown to a yellowish color.

One source described the sulphitation process as done separately (to ‘bleach’ the juice) before going to the lime and water solution, which alkalizes the juice and clarifies it – turning brown to yellow.

At this stage, the juice is also clarified to remove all the particles and remaining fiber/sludge in the juice before it is boiled.

Note: The leftover pulpy/fibrous material from the sugar cane is called “bagasse“ and is used as a biofuel. There is also a sludgy substance leftover called “mud,” which fertilizes the sugarcane fields.

Crystallize the Syrup

Once the juice is clarified, it’s time to boil it into a syrup. It will be boiled to concentrate to a level of around 50-65% sugar.

This is further encouraged through a process of crystallization called “seeding”. A milky solution of alcohol and glycerin is slowly added to the syrup, drawing out the sugar and converting it to crystals. As the mixture further boils, the liquid will evaporate as more crystals grow and become a dense paste of suspended sugar crystals in a syrup (mother liquor). This is referred to as massecuite.

Extract The Sugar Crystals & Molasses

Then, it’s time for the process of centrifugation. This is done to extract the syrup’s crystals from the massecuite by spinning them in massive centrifuges (like washing machines). These machines spin at something between 1000-2800RPM, which draws out the molasses to the machine’s outer shell. Meanwhile, the solid crystals remain in the inner basket. This is raw sugar (which still contains some molasses).

The removed molasses are then removed and sent to storage tanks. Meanwhile, the remaining raw sugar crystals are washed and dried (in a machine like a laundry dryer). There seem to be some differing techniques at this stage. Some suggest further clarification is done, and some simply mention the washing and drying process.

Finally, the sugar is sieved through various wire meshes (for superfine, fine, and coarse table sugar).

Sugar Beets

The way sugar beets are processed is very similar to sugar cane, apart from the beginning of the process.

First, the beets (which look somewhere between beetroot and a parsnip) are harvested and washed. This removes any sediment (rocks, weeds, etc.).

Next, the sugar is extracted and purified. This is done by slicing the beets and soaking them in boiling water to break down the cell membranes. This then extracts the sucrose by osmosis. These beet slices are then placed into a diffusion chamber to extract as much sugar as possible into a sugar juice.

The remaining pulp (which is non-sugary) is pressed and dried – often used as animal feed.

Beet Sugar Vs. Cane Sugar

Though the two are technically identical chemically speaking and almost identical in nutritional composition (as they’re essentially pure sucrose), the flavors and reactions in recipes can differ.

Cane sugar is said to have a lingering, sweeter aftertaste and fruity aroma and apparently will caramelize more easily. In comparison, beet sugar is a little more earthy, with a “darker,” almost burn aftertaste and a crunchier texture. Though most of us can’t tell the difference in flavor. There are, however, several reports on the change in how they caramelize and react within baked goods.

Likewise, the brown sugar from both sources has differences too. Most notably, beet sugar often contains sugar cane molasses due to the lesser quality of the beet sugar molasses (which aren’t as sweet).

Fun Fact: In the US, an estimated 95% of sugar beets are genetically modified; thus, some consumers may prefer cane sugar over beet sugar – to avoid GMOs. Though, that topic is a debate in and of itself.

FAQs

How are sugar molasses used?

As well as being added back into sugar to create brown sugar, sugar cane molasses are also used for sweetening and flavoring foods.

In comparison, sugar beet molasses (which aren’t very sweet) are used more for commercial uses and animal feed.

Is white sugar bleached?

This is a common misconception – no! Or at least not in the way we think of “bleaching”. Sugar crystals are naturally white once the molasses have been removed.

In some cases, bone char (like activated charcoal) is used to draw out all the impurities from sugar cane crystals, so they become white (which, as previously said, ARE naturally white). So this is what some people think of as the “bleaching” process – but is referred to as a “purification” process.

This is also important to note for vegetarians/vegans, who may prefer to consume beet sugar instead.

Can I make brown sugar at home?

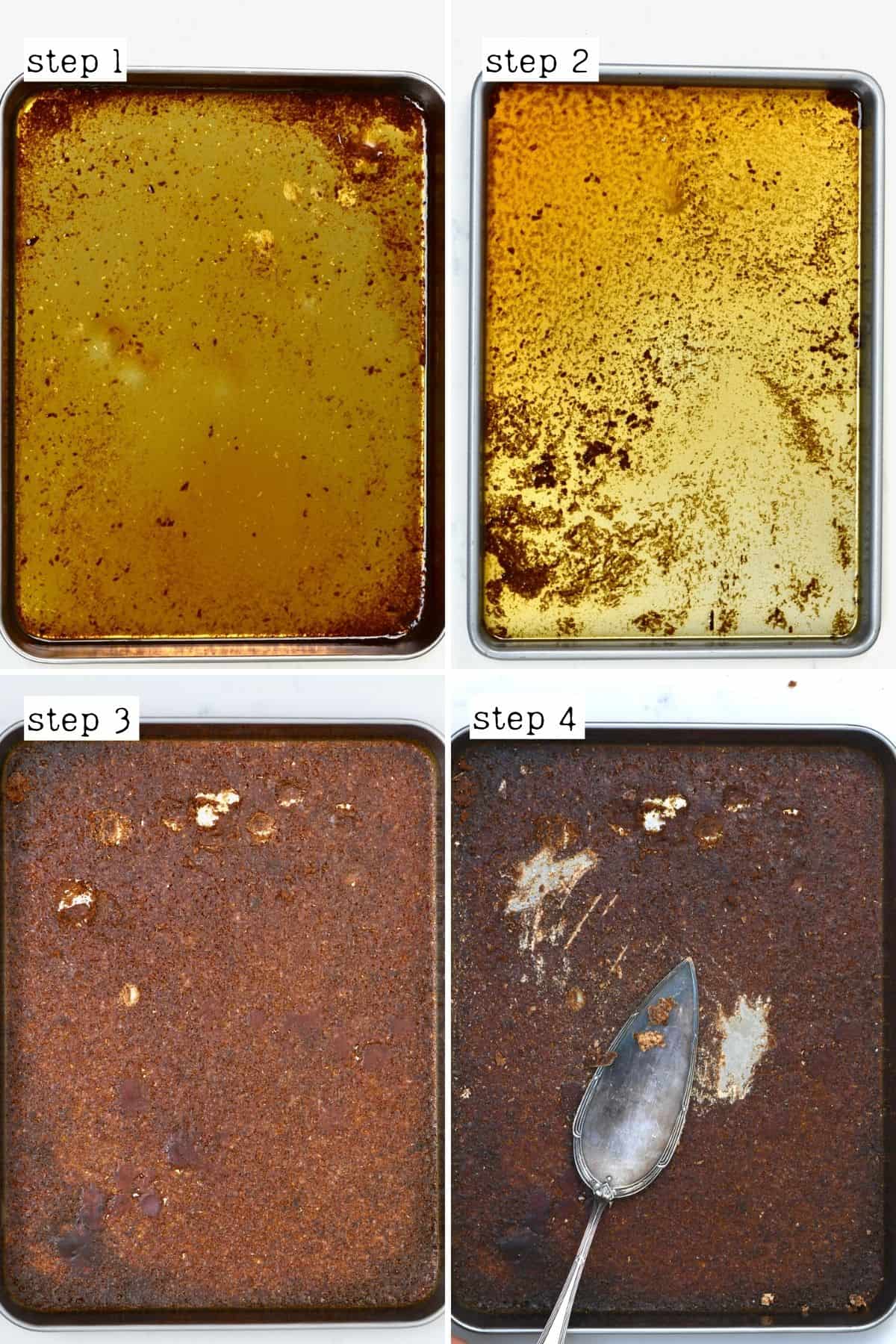

Yes – you just need white sugar and molasses. The process is very quick and you can make brown sugar whenever needed. Check my blog post for the exact measurements and lots of tips on storing and alternative substitutes.

How to tell if sugar is from cane or beet?

This can be tricky if it’s not mentioned on the pack. For packs that just list “sugar” it may be either – or a blend.

This depends on where you live too. Apparently, 55-60% of sugar produced in the US is made from sugar beets. In the UK, sugar beet is also the version grown domestically. Cane sugar is imported in – I’m not sure of the exact %s.

Related Posts

- Baking Powder vs. Baking Soda

- How to Make Brown Sugar at Home? (Light & Dark Brown)

- A Comprehensive Guide To Vegan, Dairy-Free Milk

- How To Make Butter (ONE ingredient)

- Super Easy Homemade Cream Cheese

- How To Make Yogurt (Natural Yogurt + Greek Yogurt)

- How To Make Tofu at Home – Two Simple Methods

- Homemade Avocado Oil (Extra Virgin – Cold Process)

- DIY Extra Virgin Coconut Oil (Cold-pressed Coconut Oil)

- The Best Kitchen Tools I Can’t Live Without (And Some That I can!)

- The Perfect Homemade Pancake Mix

Let me know in the comments below if you have any further questions about the process to make sugar!